DAEMWOOL eco-panels

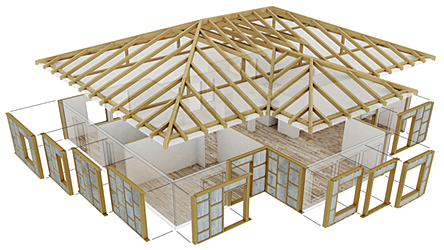

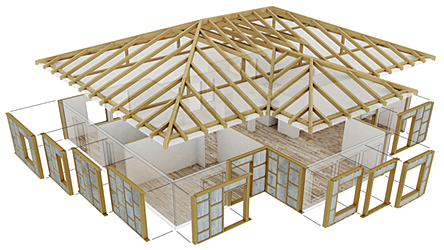

Daemwool eco-panels represent the universal construction element simplifying and speeding-up the assembly works while preserving accuracy and quality of the work.

Daemwool eco-panels represent the universal construction element simplifying and speeding-up the assembly works while preserving accuracy and quality of the work.

They are environment-friendly, allow water vapour diffusion and they are ideal for the construction of low-energy, passive and bio-passive houses capable of the future reduction of the operational costs of house inhabitants down to zero.

The basic construction material is wood and sheep wool. The great ability of sheep wool to absorb humidity prevents condensation, regulates air humidity and create a pleasant climate in a room.

The ready-made panels should be simply fixed to the lower belt structure.

Daemwool eco-panels need not to be assembled directly onto the foundation slab, they may be mounted using cheaper way to micro-posts.

Daemwool eco-panels are made in basic, door and window version.

Download the technical drawing with an exact specification of various eco-panel types (PDF)

Daemwool eco-panel advantages

- fast assembly

- the possibility of choice between low-energy or passive standard

- the possibility of choice of facade and the internal surface treatment

- the lowest value of released Co2 during the production of used material

Daemwool eco-panel examples

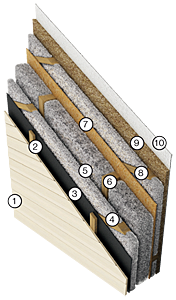

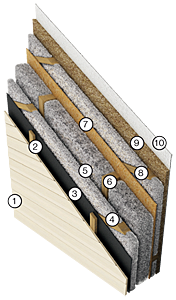

Daemwool panel + internal and external thermal insulation 80 + vented facade

1. facade cladding

1. facade cladding

2. vertical lathing (SM/JD 30/60) - vented gap

3. safety high-diffusion hydro-insulation

4. horizontal lathing SM/JD 80/60 at 625 mm, filler DAEMWOOL 80 mm

5. safety high-diffusion hydro-insulation (the part of a panel)

6. carrying frame SM/JD 60/160 at 625 mm, filler 2x DAEMWOOL 80 mm

7. OSB/3 12 mm

8. horizontal lathing SM/JD 80/60 at 625 mm, filler DAEMWOOL 80 mm

9. hofatex/steico - 40 mm

10. clay plaster PICAS - 10 mm

U = 0.132 W/(m2.K)

total CO balance for materials used for wall construction: -156.4 kg CO /m of the wall

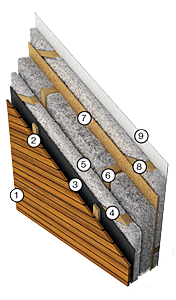

Daemwool panel + internal thermal insulation 40 + vented facade

1. facade cladding

1. facade cladding

2. safety high-diffusion hydro-insulation

3. carrying frame SM/JD 60/160 á 625 mm, filler 2x DAEMWOOL 80 mm

4. OSB/3 12 mm

5. horizontal lathing SM/JD 40/60 á 625 mm, filler DAEMWOOL 40 mm

6. vapour cellulose barrier

7. interior wooden cladding

U = 0.232 W/(m2.K)

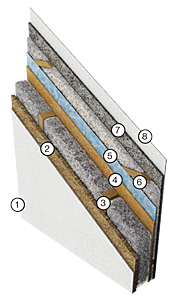

Daemwool panel + internal and external thermal insulation 80 + vented facade

1. facade cladding

1. facade cladding

2. vertical lathing (SM/JD 30/60) - vented gap

3. safety high-diffusion hydro-insulation

4. horizontal lathing SM/JD 80/60 at 625 mm, filler DAEMWOOL 80 mm

5. safety high-diffusion hydro-insulation (the part of a panel)

6. carrying frame SM/JD 60/160 at 625 mm, filler 2x DAEMWOOL 80 mm

7. OSB/3 12 mm

8. horizontal lathing SM/JD 80/60 at 625 mm, filler DAEMWOOL 80 mm

9. interior wooden cladding

U = 0,144 W/(m2.K)

Daemwool panel + internal thermal insulation 40 + vented facade

1. facade cladding

1. facade cladding

2. safety high-diffusion hydro-insulation

3. carrying frame SM/JD 60/160 at 625 mm, filler 2x DAEMWOOL 80 mm

4. OSB/3 12 mm

5. horizontal lathing SM/JD 40/60 at 625 mm, filler DAEMWOOL 40 mm

6. interior wooden cladding

U = 0,232 W/(m2.K)

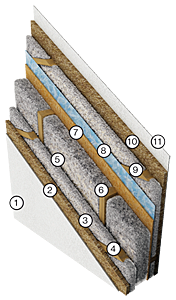

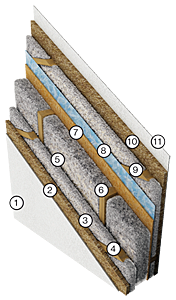

Daemwool panel + internal and external thermal insulation 80 + contact facade

1. Plaster system for hofatex/steico

1. Plaster system for hofatex/steico

2. Hofatex/steico 40 mm

3. Safety high-diffusion hydro-insulation

4. Horizontal lathing SM/JD 80/60 at 625 mm, filler DAEMWOOL 80 mm

5. Safety high-diffusion hydro-insulation (the part of a panel)

6. Carrying frame SM/JD 60/160 at 625 mm, filler 2x DAEMWOOL 80 mm

7. OSB/3 12 mm

8. Vapour barrier

9. Horizontal lathing SM/JD 80/60 at 625 mm, filler DAEMWOOL 80 mm

10. hofatex/steico - 40 mm

11. clay plaster PICAS - 10 mm

U = 0,118 W/(m2.K)

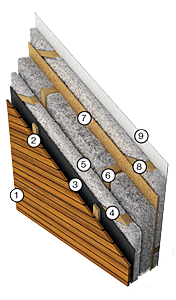

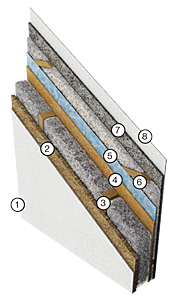

Contact hofatex facade

1. plaster system on hofatex/steico

1. plaster system on hofatex/steico

2. hofatex/steico 40 mm

3. carrying frame SM/JD 60/160, filler 2x DAEMWOOL 80 mm

4. OSB/3 12 mm

5. vapour barrier

6. horizontal lathing SM/JD 40/60, filler DAEMWOOL 40 mm

7. KRUPINIT (Heraklith) 25 mm

8. clay plaster PICAS 13 mm

U = 0,183 W/(m2.K)

Daemwool eco-panels represent the universal construction element simplifying and speeding-up the assembly works while preserving accuracy and quality of the work.

Daemwool eco-panels represent the universal construction element simplifying and speeding-up the assembly works while preserving accuracy and quality of the work.

1. facade cladding

1. facade cladding 1. facade cladding

1. facade cladding 1. facade cladding

1. facade cladding 1. facade cladding

1. facade cladding 1. Plaster system for hofatex/steico

1. Plaster system for hofatex/steico 1. plaster system on hofatex/steico

1. plaster system on hofatex/steico